Environmental Compliance

Our broad range of environmental compliance services for industrial and commercial facilities supports client objectives from site selection and facility planning through the permitting process and operations. Our services include Air Quality, Chemical Management, Water Quality and Oil Management, Land Quality, Solid Waste Management, and more.

All environmental compliance services can be provided in both English and Spanish.

Air Quality

BCA’s engineers and environmental professionals are experienced with permitting new facilities through the New Source Review process and modifying existing permits. Our expert Environmental Compliance Team has extensive experience with NESHAP and NSPS regulations.

BCA’s expertise includes emission estimation for criteria pollutants, HAPs, CO2e and other pollutants of concern as required by permit or rule, whether reported or maintained on site. We have provided these services for permitting, reporting, disclosure projects and other internal reporting purposes for hundreds of clients across North America.

Our Environmental Compliance Team prepares and files all routine reports required by permit or by rule (e.g., quarterly and annual emission, NSPS, NESHAP reports, etc.). With extensive experience in various state and federal disclosure reporting software platforms in the United States, Canada and Mexico, our Team has the capability to meet all our clients’ regulatory reporting needs.

Using various recognized standards, BCA’s greenhouse gas disclosure experts calculate emissions to ensure adherence to carbon reduction initiatives. Our comprehensive assessment evaluates the environmental impact of an operation, allowing clients to accurately disclose CO2e and develop a strategy to meet carbon reduction goals.

Utilizing our nationwide network of stack testing partners, we guide clients through facility exhaust outlet prep, filing notifications, test day project management, test day record keeping, results and report review and final submittal to the appropriate regulatory agency. Our expertise combined with the stack testing firms’ experience providing accurate results and quality reporting ensures client satisfaction and regulatory compliance while eliminating costly errors.

Our Environmental Compliance Team provides a detailed analysis of operations and work practices to guide clients and determine facility regulatory compliance. BCA is experienced with reporting and filing through state and federal programs using various filing systems (e.g., CDX).

BCA’s environmental professionals provide and facilitate air quality training that meets required state specific standards.

BCA’s engineers and environmental professionals have provided air emissions consulting services since the Clean Air Act amendments of the 1990s. Under the authority of Section 114 of the Clean Air Act, Information Collection Requests (ICR) are made regarding a variety of facility operations. BCA’s expert team of air compliance specialists often assists clients to address ICRs and guide them through often complex regulatory inquiries.

Legal action, including litigation, can be a difficult and challenging experience for our clients. BCA works to reduce the disruption and distractions that often arise from such events. Our Environmental Compliance Team serves as the liaison between a client facility, regulators, and legal counsel. This often includes providing assistance to locate records, providing technical data, evaluating regulations and their applicability, and analyzing a facility’s compliance with regulatory standards. Our team will also assist clients to prepare responses associated with litigation and other legal actions.

Our Environmental Compliance Team provides clients with additional, relevant air related services including Risk Management Plans, Preventive Maintenance Plans, and Emergency Reduction Plans.

Chemical Management

Our chemical management specialists provide Tier II reporting nationwide. Services range from on-site visits to conducting chemical inventories to complete the Tier II to remotely working with facility personnel to gather information needed to complete an inventory and file the report by the annual March 1st deadline.

BCA’s chemical management specialists provide Form R and A reporting for clients nationwide. Services range include on-site visits, assessments of what is being manufactured, processed, or otherwise used to estimate emissions, discharges, and waste generated, and remotely working with facility personnel to gather information needed to complete Form R and A reports by the annual July 1st deadline.

Our Environmental Compliance Team assists clients to effectively implement chemical use and storage hazard communication at facilities throughout North America. As with all environmental compliance services, communications can be provided in both Spanish and English and in digital or hard copy form, as needed.

The US Department of Transportation requires HAZMAT Transportation Training for all employees that receive, handle, and prepare hazardous materials for shipment at least every three years. BCA’s HAZMAT Transportation Training program increases client’s employee safety awareness, by providing consulting, guidance, and work instructions related to how hazardous materials need to be handled.

BCA’s Environmental Compliance Team provides permitting services for storage tank usage on client facilities. Permitting requirements often vary by state. However, most states require above ground storage tanks holding flammable materials to be permitted through the state department of homeland security or other emergency services agency. BCA is equipped to assess tanks and contents and file the necessary permits as required by state rule.

BCA’s Environmental Compliance Team develops chemical inventory and tracking tools for client facilities across the nation. These tools are valuable assets for a range of reporting requirements, including Tier II and OSHA SDS, among others. Additionally, BCA develops inventories and tracking tools for clients as part of their ongoing environmental assurance programs.

A hazardous substance determination may be required by federal, state, or internal programs to assess and categorize all substances at a client facility, including those regulated by EPA, OSHA, and Canadian and Mexican environmental regulatory authorities. BCA’s hazardous substance specialists facilitate chemical inventories and identify special handling and reporting thresholds described in local, state and federal rules for clients and their facilities located across North America.

TSCA 40 CFR Part 711 requires some manufacturers and/or importers and exporters of chemicals to submit a Chemical Data Report (CDR, also known as Form U) every four years. BCA’s Environmental Compliance Team assists clients to determine which chemicals at their facilities require reporting and file the appropriate reports in a timely manner on their behalf

BCA’s Environmental Compliance Team provides SDS management services to clients throughout North America. SDSs can be managed in a variety of ways, including hard copy storage on site, PDFs on a shared cloud server, or on client owned software. Combined with our chemical inventory and hazardous substances determination, BCA assists clients to maintain accurate SDS files that ensure employees have quick access to current and past SDSs.

BCA’s Environmental Compliance Team offers a custom suite of services to clients seeking to manage their environmental compliance. Additional chemical management services include international standards such as REACH and RoHAS, California’s Prop 65, and Life Cycle Analyses (models the environmental impacts of the various stages and processes associated with industrial manufacturing).

Water Quality and Oil Management

Facilities with more than 1,320 gallons of oil on site may be required to implement an SPCC Plan in accordance with 40 CFR 112. This applies to all process and storage containers with a volume equal to or greater than 55 gallons. BCA’s water quality specialists have prepared hundreds of SPCC Plans and trained client facility personnel on the plan and its implementation. BCA’s on-staff licensed Professional Engineers are available to certify SPCC Plans when required by regulatory authorities and/or rule.

SWPPPs and/or BMPs are often required for facilities where stormwater is exposed to industrial materials and/or releases. These include facilities governed by the General stormwater permit rule or those that have been issued an Individual stormwater permit by the regulatory agency. BCA’s Environmental Compliance Team prepares and implements SWPPPs and BMPs for facilities, including identifying potential pollutant sources, outlining controls to reduce pollutants, maintenance/inspection procedures, and record keeping. BCA’s stormwater management professionals also provide SWPPP training to facility staff that meets or exceeds regulatory requirements, and stormwater sample collection training, ensuring proper sample integrity is maintained.

BCA’s Environmental Compliance Team is comprised of environmental scientists and engineers who have prepared hundreds of wastewater discharge permits and permit modifications for clients across North America. Our expertise includes permitting facilities that discharge wastewater to local Publicly Owned Treatment Works (POTWs) or those that discharge to regulated bodies of water. When pretreatment is required, BCA provides additional support in the design, procurement, and installation of the treatment system.

BCA’s Water Quality Team has decades of experience in preparing new client facility stormwater discharge permits or modifying existing stormwater discharge permits. BCA’s water quality specialists have prepared hundreds of permits and permit modifications for clients across North America and will tailor industrial stormwater permits to the unique requirements for each facility and to meet client’s needs.

BCA’s staff of environmental professionals and certified wastewater operators provide sample collection and analysis services, including routine wastewater and stormwater sampling of facility effluent to complete Discharge Monitoring Reports. Our Environmental Compliance Team also provides training and preparation of work instructions for facility staff to conduct in-house sampling, if desired.

Federal regulation (40 CFR 112.7) requires annual spill prevention and response training for all personnel that handle oil at a facility. BCA’s Senior Environmental Compliance specialists and engineers provide on-site training that is customized to client facility conditions, operations, and oil handling practices.

General and Individual stormwater permits require annual training for personnel who interact with industrial materials exposed to stormwater, and for those who implement Best Management Practices at a facility. BCA’s Environmental Compliance Team provides onsite custom stormwater training that is tailored to the operations conditions, industrial materials being handled, and oil handling practices of the facility.

BCA’s Environmental Compliance Team guides clients throughout North America through the tank integrity testing process from start to finish, including connecting the client with a trusted and vetted tank integrity tester from our network in their region, preparing the facility for testing, filing required notifications to regulators, test day project management, test day record keeping, results and report reviews, and submittal of the final report to the regulatory agency.

BCA provides certified wastewater operator services to client facilities nationwide. This allows facility personnel to focus on their business, while BCA provides the personnel necessary to manage wastewater operations to meet regulatory requirements.

Facilities that discharge wastewater to a POTW may be required to implement an SPCP to identify, mitigate and control sources of spills and illicit discharges to the wastewater system, including process and storage containers. Our Environmental Compliance Team prepares, implements, and provides SPCP training to client facility staff nationwide. Our licensed Professional Engineers certify SPCPs when required by local or state regulatory authorities.

Our team of engineers, geologists, and environmental scientists have provided UST leak detection, integrity testing, soil and groundwater assessment, tank closure, leaking UST remedial design, and leaking UST remediation services for clients nationwide. Working with clients and regulators, BCA prepares coordinated, compliant tank closure and cleanup plans, implements and manages UST closure and site remedial actions (if necessary), prepares associated regulatory reports, and guides the project through final regulatory approval of the UST closure process.

BCA provides comprehensive spill response services, resulting in expedited cleanup response and reduced costs associated with spill incidents. BCA’s experienced Spill Response Team coordinates with cleanup contractors to notify all appropriate regulatory agencies; develop and initiate remediation procedures; coordinate communication between clients and regulators; investigate and remediate impacted soil, groundwater, and/or surface waters; conduct initial and confirmation sampling as necessary; and prepare regulatory closure reports.

Legal action, including litigation, can be a difficult and challenging experience for our clients. BCA works to reduce the disruption and distractions that often arise from such events. Our Environmental Compliance Team serves as the liaison between a client facility, regulators, and legal counsel. This often includes providing assistance to locate records, providing technical data, evaluating regulations and their applicability, and analyzing a facility’s compliance with regulatory standards. Our team will also assist clients to prepare responses associated with litigation and other legal actions.

Facilities that provide drinking water from an onsite well rather than a local water supply may be required to obtain a drinking water permit as a Noncommunity Water System and comply with state and local regulations for monitoring, treating, and reporting. BCA’s Compliance Team provides experienced drinking water specialists that prepare permits as required, assist with treatment decisions, and provide on-going sampling support as required by the permit.

BCA’s experienced Compliance Team provides a variety of other relevant water related services including: Preparedness, Prevention, and Contingency (PPC) Plans, Flow Measurement Plans, Pretreatment Contingency Plans, Pretreatment System Consulting, Facility Response Plans, regulatory Water Withdrawal Reporting, and Wellhead Protection permitting and Plans.

Land Quality and Solid Waste Management

All Large Quantity Generators (LQG’s) must report the nature, quantities and disposition of hazardous waste generated at their facility at least once every two (2) years to the EPA (Biennial Report form 8700-13A/B). Additionally, state agencies may require more frequent reporting for LQG’s and Small Quantity Generators (SQG’s). BCA’s team of environmental professionals are highly experienced in reviewing hazardous waste manifests, assessing points of generation of hazardous wastes, and preparing and filing RCRA Hazardous Waste Manifest Biennial Reports to EPA by the required March 1st deadline of each even numbered year.

Annual Training (changed the heading name on this one)

40 CFR 262 requires LQG’s to provide initial and annual training for all personnel whose job responsibilities bring them into contact with hazardous waste, have a responsibility for management of hazardous waste, may respond to a hazardous waste emergency, or those who review or sign uniform hazardous waste manifests. 40 CFR 262 requires that SQG’s employees are thoroughly familiar with proper waste handling and emergency procedures. BCA’s hazardous waste professionals provide custom on-site initial and annual training courses that are tailored to the facility, site waste practices, and staff who handle and manage hazardous waste

40 CFR 262 requires Large Quantity Generators (LQG’s) to implement a Contingency Plan designed to minimize hazards to human health or the

environment from fires, explosions, or any unplanned sudden or non-sudden release of hazardous waste or hazardous waste constituents to air, soil, or surface water. Contingency Plans must also include a Quick Reference Guide that is submitted to local emergency authorities. BCA’s hazardous waste professionals are experienced in preparing and implementing Contingency Plans, including training facility staff on the procedures and requirements of their site-specific Contingency Plan

One of the procedures necessary for a hazardous waste generator to safely and legally transport hazardous waste, is completing a waste stream profile. BCA’s team of experienced waste professionals has assisted hundreds of clients to identify, categorize, and assess waste streams at the point of waste generation, and to review applicable Land Quality regulations to determine how the waste stream should be profiled and managed. Our team also coordinates with the disposal facility and hauler to receive approval for transport and disposal of the wastes.

During waste stream profiling, some waste will need to be sampled and tested by a laboratory to determine if they should be categorized as RCRA Hazardous Waste. BCA’s team of waste professionals utilize their years of experience to assess raw materials and processes that create a waste stream. We then employ appropriate sampling and analytical methods to ensure that waste streams are categorized, stored, and handled in a compliant manner.

RCRA requires anyone who handles hazardous waste (generator, transfer facility, and/or a treatment, storage, or disposal facility) to notify their state regulatory agency (as authorized by EPA) of their regulated waste activities, by applying for and receiving a RCRA identification number. BCA’s waste management professionals are proficient with the Site ID application process and can file on behalf of clients through the state agency or through the EPA directly (if the facility is not in an authorized state). Note that Site ID’s are location specific. If a facility changes location, a new ID must be applied for as the old one is no longer valid.

An episodic event, as defined in 40 CFR 262, is an activity that does not normally occur during a generator’s operations and that causes that generator to exceed the threshold for its normal generator category during that month. Episodic events may be planned (e.g. plant cleanout) or unplanned (e.g. spill). Small Quantity and Very Small Quantity Generators are allowed by EPA one (1) planned or unplanned episodic waste generation event per year, with the provision to petition for a second event if necessary in the same calendar year. BCA’s waste management professionals have assisted many clients and facilities to appropriately manage and discard episodic wastes under this exclusion. Our team of professionals file the notification for the episodic event, coordinate waste removal, maintain appropriate records and inventory, and file closure notifications to the EPA or implementing state regulatory agency.

Large Quantity Generators of hazardous waste must follow the closure requirements described in 40 CFR 264 which includes pre-notifications and certifications that the site is not contaminated. Our experienced waste management team includes Professional Engineers and Certified Hazardous Materials Managers to assess the facility to ensure it is not contaminated or develop a clean-up plan when needed. We will file the required notifications and guide the facility until the facility receives closure approval from the EPA or implementing state regulatory agency.

As defined in 40 CFR 262, at least weekly, a LQG of hazardous waste must inspect central accumulation areas for leaking containers and for deterioration of containers caused by corrosion or other factors. For facilities located in Northern Indiana, Southern Michigan and Northwest Ohio, an experienced professional from BCA’s waste management team can visit the site to conduct the required weekly hazardous waste inspections of waste generating and storage areas.

Under the authority of Section 3007 of RCRA, the EPA and authorized state regulatory agencies can request information from anyone who generates, stores, treats, transports, disposes of, or otherwise handles or has handled hazardous waste, relating to such waste. BCA’s engineers and environmental professionals have provided hazardous waste consulting services since the Hazardous and Solid Waste Amendments of 1984 and we have guided our clients through many, often complex, regulatory inquiries, with experience related to nearly any request that the EPA may issue to a facility.

Under RCRA Subtitle D, new facilities wishing to conduct solid waste operations must submit the appropriate permits or registration applications and receive approval from the EPA or implementing state regulatory agency before beginning construction and operation of the facility. BCA’s waste management team is experienced with permitting new facilities and modifying existing permits, including changes to design, operation, monitoring, and maintenance activities.

Some nonhazardous solid waste such as uncontaminated rocks, bricks, concrete, road demolition waste materials, dirt, etc. may be legitimately used. Legitimate use of solid waste, depending upon the type of waste and how it is to be used, may require a registration approval or a processing facility permit from the state regulatory agency. BCA’s waste management team and engineers are knowledgeable of solid waste facilities and the rules to make an accurate assessment of processing and waste materials to file for the appropriate approvals for legitimate use as appropriate.

Facilities performing the recycling of hazardous secondary material (HSM) under the generator-controlled exclusion of 40 CFR 261.4(a)(23) must perform a legitimacy determination as specified in 40 CFR 260.43 and maintain documentation of the determination onsite. BCA’s waste professionals, engineers, and environmental professionals can conduct the required evaluations and prepare documentation to support that the recycling and reuse practices are legitimate. Conversely, if a facility is concerned how non-hazardous waste is being handled and would like the value stream to be audited, BCA can perform waste audit services as necessary to identify and document facility waste handling procedures.

Solid Waste facilities are required to develop and implement a Facility Operations Plan to document work practices and describe contingencies to prevent and control releases or other emergency situations. BCA’s staff of waste management and environmental professionals are highly experienced with developing Facility Operations Plans and will prepare and implement custom solid waste operations plans for client facilities, including training facility staff on the implementation of the plan.

BCA’s experienced waste management team assists client facilities to manage and minimize their wastes by identifying each waste stream at the point of generation and developing a waste inventory, including the type, amount, and location of each waste stream. The inventory identifies the category of each waste stream and specifies how each must be handled, managed, and shipped in accordance with applicable local, state, and federal EPA, DOT and OSHA requirements.

Legal action, including litigation, can be a difficult and challenging experience for our clients. BCA works to reduce the disruption and distractions that often arise from such events. Our team of waste management professionals serves as the liaison between a client facility, regulators, and legal counsel. This often includes providing assistance to locate records, providing technical data, evaluating regulations and their applicability, and analyzing a facility’s compliance with regulatory standards. Our team will also assist clients to prepare responses associated with litigation and other legal actions.

BCA’s experienced waste management professionals provide a variety of other relevant waste related services including: Solid Waste Transfer Station Permits, Marketing and Distribution Permits, Landfill Operator, Waste Removal Coordination, and Recycling Coordination.

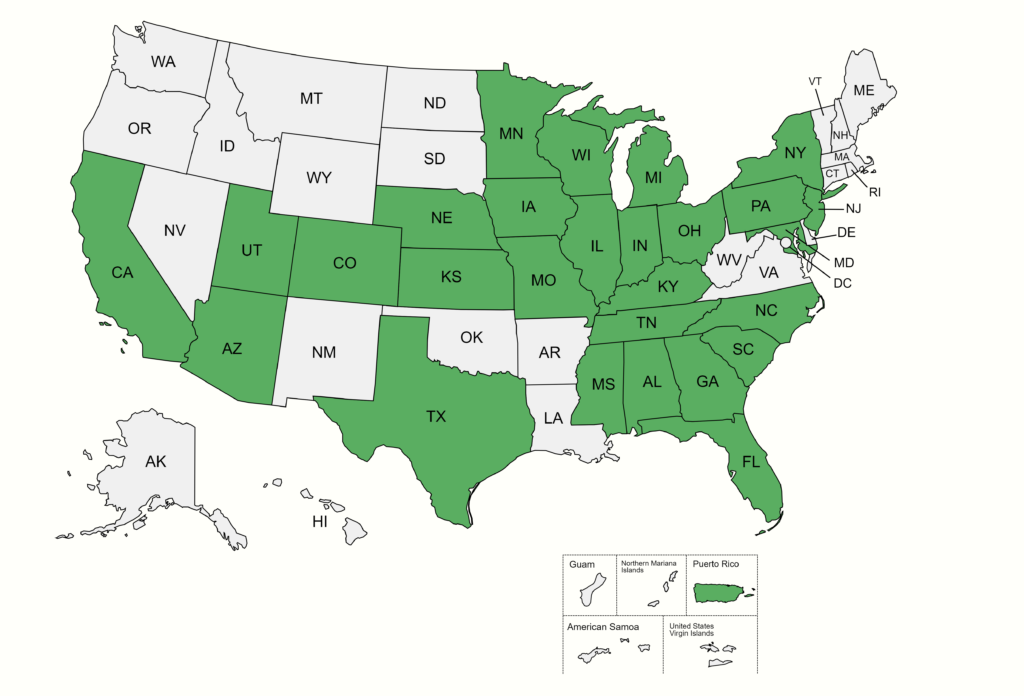

We primarily serve clients in Indiana, Michigan, Illinois, Kentucky and Ohio, but we have completed work over 25 US states, plus Puerto Rico, Ontario, CAN and Nuevo Leon, MX